The general characteristics exhibited by O Seal Male Connector are good corrosion resistance, general resistance, good strength and toughness and pitting resistance to acidic and other chloride environments. The tests certifications are very important and so they are offered with male connector to the clients. The tests documents offered are manufacturer TC in conformance with EN 10204, raw material report and other standard inspection reports.

We Make O Seal Male Connector in Various Grade, Diameters & Thickness as per Customer Drawings & Specifications

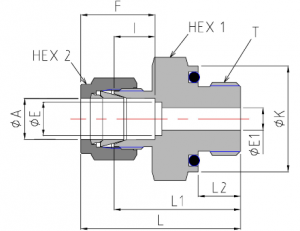

| Part No. | ØA | ØE | ØE1 | L | I | L1 | L2 | F | ØK | Hex 1 | Hex 2 | T | O-Ring |

| Tube OD | UNF | AS568 | |||||||||||

| DI-FIT/OMC/1-2-* | 1/16. (1.59) |

0.05 (1.3) |

0.09 (2.3) |

1.06 (26.9) |

0.19 (4.9) |

0.90 (22.9) |

0.34 (8.6) |

0.35 (8.9) |

0.55 (14.0) |

9/16. | 5/16. | 5/16-24. | -011 |

| DI-FIT/OMC/2-2-* | 1/8. (3.18) |

0.09 (2.3) |

0.09 (2.3) |

1.29 (32.7) |

0.25 (6.4) |

20.24 (6.0) |

0.34 (8.6) |

0.51 (13.0) |

0.55 (14.0) |

9/16. | 7/16. | 5/16-24. | -011 |

| DI-FIT/OMC/3-3-* | 3/16. (4.76) |

0.12 (3.0) |

0.12 (3.0) |

1.37 (34.7) |

0.28 (7.2) |

1.10 (28.0) |

0.38 (9.7) |

0.54 (13.8) |

0.61 (15.4) |

5/8. | ½. | 3/8-24. | -012 |

| DI-FIT/OMC/4-4-* | ¼. (6.35) |

0.19 (4.8) |

0.19 (4.8) |

1.52 (38.7) |

0.31 (7.9) |

1.23 (31.2) |

0.41 (10.4) |

0.61 (15.4) |

0.73 (18.5) |

¾. | 9/16. | 7/16-20. | -111 |

| DI-FIT/OMC/5-5-* | 5/16. (7.94) |

0.25 (6.4) |

0.25 (6.4) |

1.61 (41.0) |

0.35 (8.8) |

1.32 (33.5) |

0.44 (11.2) |

0.64 (16.3) |

0.86 (21.9) |

7/8. | 5/8. | 1/2-20. | -112 |

| DI-FIT/OMC/6-6-* | 3/8. (9.53) |

0.28 (7.1) |

0.28 (7.1) |

1.67 (42.5) |

0.37 (9.5) |

1.38 (35.0) |

0.47 (11.9) |

0.67 (17.0) |

0.93 (23.6) |

15/16. | 11/16. | 9/16-18. | -113 |

| DI-FIT/OMC/8-8-* | ½. (12.7) |

0.41 (10.4) |

0.41 (10.4) |

1.81 (46.1) |

0.50 (12.7) |

1.41 (35.8) |

0.47 (11.9) |

0.91 (23.0) |

1.10 (28.0) |

1-1/8. | 7/8. | 3/4-16. | -116 |

| DI-FIT/OMC/8-12-* | ½. (12.7) |

0.41 (10.4) |

0.62 (15.8) |

2.06 (52.3) |

0.50 (12.7) |

1.65 (42.0) |

0.56 (14.2) |

0.91 (23.0) |

1.48 (37.6) |

1-1/2. | 7/8. | 1-1/16-12. | -215 |

| DI-FIT/OMC/10-10-* | 5/8. (15.88) |

0.50 (12.7) |

0.50 (12.7) |

1.94 (49.3) |

0.56 (14.3) |

1.54 (39.0) |

0.51 (13.0) |

0.97 (24.6) |

1.35 (34.4) |

1-3/8. | 1 | 7/8-14. | -119 |

| DI-FIT/OMC/12-12-* | ¾. (19.05) |

0.62 (15.8) |

0.62 (15.8) |

2.06 (52.3) |

0.56 (14.3) |

1.65 (42.0) |

0.56 (14.2) |

0.97 (24.6) |

1.48 (37.6) |

1-1/2. | 1-1/8. | 1-1/16-12. | -215 |

| DI-FIT/OMC/16-16-* | 1. (25.4) |

0.89 (22.5) |

0.89 (22.5) |

2.31 (58.6) |

0.75 (19.1) |

1.81 (46.0) |

0.56 (14.2) |

1.24 (31.6) |

1.73 (44.0) |

1-3/4. | 1-1/2. | 1-5/16-12. | -219 |

Material of Construction

| Monel : Grade: Monel 400, Monel K500, Monel R-405 Nickel : Grade: Nickel 200, Nickel 201 Inconel : Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718 Incoloy : Grade: Incoloy 800, Inconel 800H, 800HT Hastalloy : Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X Titanium : Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11 Stainless Steel : Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 Carbon Steel : Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 Duplex Steel: Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61 Alloy Steel: Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19 |

Call +91 9833907060

Call +91 9833907060 Send E-mail

Send E-mail