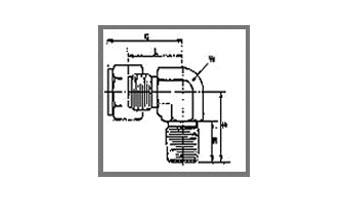

DI-FIT . is a leading Male Elbow Manufacturers in Mumbai, India. Our qualitative range of Male Elbow is exclusively designed for several piping applications of various industries Such as steel factories, chemical industries, petrochemical industry, fire protection systems, Plumbing, commercial and residential application, etc. Male Elbow is designed and developed in accordance with the IQS (International Quality Standards). We also offer customized Male Elbow as per the customer’s requirement.

| Metric tubing | |||||||||

| PART NO. | Tube O.D mm |

NPT thread |

C | H | L | R | W | Min bore | |

| mm | mm | mm | mm | inch | mm | ||||

| DI-FIT/ME/3-1/8 | 3 | 1/8. | 23.3 | 18.3 | 16.7 | 9.7 | 5/16. | 2.4 | |

| DI-FIT/ME/3-1/4 | 3 | ¼. | 24.9 | 23.8 | 18.3 | 14.2 | 9/16. | 2.4 | |

| DI-FIT/ME/4-1/8 | 4 | 1/8. | 24.1 | 18.3 | 17.5 | 9.7 | 5/16. | 3.0 | |

| DI-FIT/ME/4-1/4 | 4 | ¼. | 25.7 | 23.8 | 19.1 | 14.2 | 9/16. | 3.0 | |

| DI-FIT/ME/6-1/8 | 6 | 1/8. | 25.8 | 19.8 | 18.3 | 9.7 | 7/16. | 4.8 | |

| DI-FIT/ME/6-1/4 | 6 | ¼. | 27.3 | 23.8 | 19.8 | 14.2 | 9/16. | 4.8 | |

| DI-FIT/ME/6-3/8 | 6 | 3/8. | 29.7 | 28.6 | 22.2 | 14.2 | ¾. | 4.8 | |

| DI-FIT/ME/6-1/2 | 6 | ½. | 32.1 | 33.3 | 24.6 | 19.1 | 7/8. | 4.8 | |

| DI-FIT/ME/8-1/4 | 8 | ¼. | 28.1 | 25.4 | 20.6 | 14.2 | 9/16. | 6.4 | |

| DI-FIT/ME/8-3/8 | 8 | 3/8. | 31.4 | 28.7 | 23.9 | 14.2 | ¾. | 6.4 | |

| DI-FIT/ME/10-1/4 | 10 | ¼. | 33.0 | 28.6 | 25.4 | 14.2 | ¾. | 7.1 | |

| DI-FIT/ME/10-3/8 | 10 | 3/8. | 33.0 | 28.6 | 25.4 | 14.2 | ¾. | 7.9 | |

| DI-FIT/ME/10-1/2 | 10 | ½. | 33.8 | 33.3 | 26.2 | 19.1 | 7/8. | 7.9 | |

| DI-FIT/ME/12-1/4 | 12 | ¼. | 34.7 | 28.6 | 24.6 | 14.2 | ¾. | 7.1 | |

| DI-FIT/ME/12-3/8 | 12 | 3/8. | 34.7 | 28.6 | 24.6 | 14.2 | ¾. | 9.5 | |

| DI-FIT/ME/12-1/2 | 12 | ½. | 36.3 | 33.3 | 26.2 | 19.1 | 7/8. | 9.5 | |

| DI-FIT/ME/12-3/4 | 12 | ¾. | 39.5 | 38.1 | 29.4 | 19.1 | 1.1/16. | 9.5 | |

| DI-FIT/ME/16 | 16 | 3/8. | 36.3 | 31.8 | 26.2 | 14.2 | 7/8. | 10.3 | |

| DI-FIT/ME/16-1/2 | 16 | ½. | 37.1 | 34.1 | 27.0 | 19.1 | 7/8. | 12.7 | |

| DI-FIT/ME/16-3/4 | 16 | ¾. | 39.5 | 38.1 | 29.4 | 19.1 | 1.1/16. | 12.7 | |

| DI-FIT/ME/18-1/2 | 18 | ½. | 39.5 | 38.1 | 29.4 | 19.1 | 1.1/16. | 12.7 | |

| DI-FIT/ME/18-3/4 | 18 | ¾. | 39.5 | 38.1 | 29.4 | 19.1 | 1.1/16. | 15.1 | |

| DI-FIT/ME/20-1/2 | 20 | ½. | 42.6 | 42.2 | 32.5 | 19.1 | 1.5/16. | 12.7 | |

| DI-FIT/ME/20-3/4 | 20 | ¾. | 42.6 | 42.2 | 32.5 | 19.1 | 1.5/16. | 15.9 | |

| DI-FIT/ME/25-3/4 | 25 | ¾. | 45.6 | 42.1 | 33.3 | 19.1 | 1.5/16. | 18.3 | |

| DI-FIT/ME/25-1 | 25 | 1. | 45.6 | 46.8 | 33.3 | 23.9 | 1.5/16. | 22.2 | |

Material of Construction:-

Monel :

Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19

Call +91 9833907060

Call +91 9833907060 Send E-mail

Send E-mail