Doshi Impex India Is Involved In Offering A Widespread Range Of Forged Couplings At Reasonable Prices To Our Clienteles. As A Supplier, Manufacturer, Stockiest, And Exporter, We Offer This Forged Sockets In Different Sizes And Thickness. Forged Socket Weld Coupling Is A Fitting That Allows Two Pipes To Get Join Together. Forged Threaded Coupling Can Be Manufactured With Socket-Weld Extremities, Threaded Extremities Or A Combination Of The Two

TYPE OF COUPLING

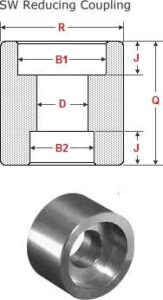

REDUCING COUPLING

The Reducing Coupling joints two different outside diameters of pipe.

FULL-COUPLING

A Full Coupling, joins pipe two pipe or to a nipple etc

HALF-COUPLING

The Half Coupling can be directly welded to the run pipe, to make a branch connection.

Reducing Coupling

The Reducing Coupling Joints Two Different Outside Diameters Of Pipe.

Specification Of Socket Weld Coupling

| Dimensions | Asme 16.11, Mss Sp-79, Mss Sp-95, 83, 95, 97, Bs 3799 |

| Size | 1/8″ Nb To 4″ Nb |

| Pressure Ratings | 2000 Lbs, 3000 Lbs, 6000 Lbs, 9000 Lbs |

| Form | Full Couplings, Reducing Coupling,Hafe Coupling |

| Production Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low Temperature Steel, Carbon Steel, Cupro Nickel |

| Dimensions Sw Reducing Couplings Asme B16.11 | |||||||

| Class 3000 | |||||||

| Nps | Socket Bore | Depth Socket | Bore Dia | ||||

| J | |||||||

| B1 | B2 | B1 | B2 | D | |||

| 3/4. | – | 1/.2 | 27.3 | 21.95 | 13 | 10 | 16.6 |

| 27.05 | 21.7 | 15 | |||||

| 1 | – | 3/4. | 34.05 | 27.3 | 13 | 13 | 21.7 |

| 33.8 | 27.05 | 20.2 | |||||

| 1 | – | 1/2. | 34.05 | 21.95 | 13 | 10 | 16.6 |

| 33.8 | 21.7 | 15 | |||||

| 1¼ | – | 1 | 42.8 | 34.05 | 13 | 13 | 27.4 |

| 42.55 | 33.8 | 25.9 | |||||

| 1½ | – | 1 | 48.9 | 34.05 | 13 | 13 | 27.4 |

| 48.65 | 33.8 | 25.9 | |||||

| 1½ | – | 3/4. | 48.9 | 27.3 | 13 | 13 | 21.7 |

| 48.65 | 27.05 | 20.2 | |||||

| 1½ | – | 1/2. | 48.9 | 21.95 | 13 | 10 | 16.6 |

| 48.65 | 21.7 | 15 | |||||

| 2 | – | 1½ | 61.35 | 48.9 | 16 | 13 | 41.7 |

| 61.1 | 48.65 | 40.1 | |||||

| 2 | – | 1 | 74.2 | 34.05 | 16 | 13 | 27.4 |

| 73.8 | 33.8 | 25.9 | |||||

| Nps | Length Coupling | Diameter Coupling | |||||

| Q | R | ||||||

| 3/4. | – | 1/2. | 35 | 36 | |||

| 1 | – | 3/4. | 38.1 | 45.2 | |||

| 1 | – | 1/2. | 38.1 | 45.2 | |||

| 1¼ | – | 1 | 38.1 | 55.1 | |||

| 1½ | – | 1 | 38.1 | 60 | |||

| 1½ | – | 3/4. | 38.1 | 60 | |||

| 1½ | – | 1/2. | 38.1 | 60 | |||

| 2 | – | 1½ | 51.3 | 74.9 | |||

| 2 | – | 1 | 51.3 | 74.9 | |||

| Dimensions Sw Reducing Couplings Asme B16.11 | |||||||

| Class 6000 | |||||||

| Nps | Socket Bore | Depth Socket | Bore Dia | ||||

| J | |||||||

| B1 | B2 | B1 | B2 | D | |||

| 3/4. | – | 1/2. | 27.3 | 21.95 | 13 | 10 | 12.5 |

| 27.05 | 21.7 | 11 | |||||

| 1 | – | 3/4. | 34.05 | 27.3 | 13 | 13 | 16.3 |

| 33.8 | 27.05 | 14.8 | |||||

| 1 | – | 1/2. | 34.05 | 21.95 | 13 | 10 | 12.5 |

| 33.8 | 21.7 | 11 | |||||

| 1¼ | – | 1 | 42.8 | 34.05 | 13 | 13 | 21.5 |

| 42.55 | 33.8 | 19.9 | |||||

| 1½ | – | 1 | 48.9 | 34.05 | 13 | 13 | 21.5 |

| 48.65 | 33.8 | 19.9 | |||||

| 1½ | – | 3/4. | 48.9 | 27.3 | 13 | 13 | 16.3 |

| 48.65 | 27.05 | 14.8 | |||||

| 1½ | – | 1/2. | 48.9 | 21.95 | 13 | 10 | 12.5 |

| 48.65 | 21.7 | 11 | |||||

| 2 | – | 1½ | 61.35 | 48.9 | 16 | 13 | 34.7 |

| 61.1 | 48.65 | 33.2 | |||||

| 2 | – | 1 | 74.2 | 34.05 | 16 | 13 | 21.5 |

| 73.8 | 33.8 | 19.9 | |||||

| Nps | Length Coupling | Diameter Coupling | |||||

| Q | R | ||||||

| 3/4. | – | 1/2. | 35 | 40.1 | |||

| 1 | – | 3/4. | 38.1 | 50 | |||

| 1 | – | 1/2. | 38.1 | 50 | |||

| 1¼ | – | 1 | 38.1 | 57.9 | |||

| 1½ | – | 1 | 38.1 | 65 | |||

| 1½ | – | 3/4. | 38.1 | 65 | |||

| 1½ | – | 1/2. | 38.1 | 65 | |||

| 2 | – | 1½ | 51.3 | 82 | |||

| 2 | – | 1 | 51.3 | 82 | |||

| Dimensions Socket Weld Couplings Asme B16.11 | |||||||

| Class 3000 | |||||||

| Nps | Socket | Depth | Bore | Socket | |||

| Bore | Socket | Dia | Wall Thk | ||||

| B | J | D | C | ||||

| 1/2. | 21.95 | 10 | 16.6 | 4.65 | |||

| 21.7 | 15 | 4.1 | |||||

| 3/4. | 27.3 | 13 | 21.7 | 4.9 | |||

| 27.05 | 20.2 | 4.25 | |||||

| 1 | 34.05 | 13 | 27.4 | 5.7 | |||

| 33.8 | 25.9 | 5 | |||||

| 1¼ | 42.8 | 13 | 35.8 | 6.05 | |||

| 42.55 | 34.3 | 5.3 | |||||

| 1½ | 48.9 | 13 | 41.7 | 6.35 | |||

| 48.65 | 40.1 | 5.55 | |||||

| 2 | 61.35 | 16 | 53.5 | 6.95 | |||

| 61.1 | 51.7 | 6.05 | |||||

| 2½ | 74.2 | 16 | 64.2 | 8.75 | |||

| 73.8 | 61.2 | 7.65 | |||||

| 3 | 90.15 | 16 | 79.5 | 9.5 | |||

| 89.8 | 46.4 | 8.3 | |||||

| 4 | 115.8 | 19 | 103.8 | 10.7 | |||

| 115.45 | 100.7 | 9.35 | |||||

| Nps | Laying Lengths | ||||||

| Coupling | Half Coupling | ||||||

| E | F | ||||||

| 1/2. | 9.5 | 22.5 | |||||

| 3/4. | 9.5 | 23.5 | |||||

| 1 | 13 | 29 | |||||

| 1¼ | 13 | 30 | |||||

| 1½ | 13 | 32 | |||||

| 2 | 19 | 41 | |||||

| 2½ | 19 | 42.5 | |||||

| 3 | 19 | 44.5 | |||||

| 4 | 19 | 47.5 | |||||

| Dimensions Socket Weld Couplings Asme B16.11 | |||||||

| Class 6000 | |||||||

| Nps | Socket | Depth | Bore | Socket | |||

| Bore | Socket | Dia | Wall Thk | ||||

| B | J | D | C | ||||

| 1/2. | 21.95 | 10 | 12.5 | 5.95 | |||

| 21.7 | 11 | 5.2 | |||||

| 3/4. | 27.3 | 13 | 16.3 | 6.95 | |||

| 27.05 | 14.8 | 6.05 | |||||

| 1 | 34.05 | 13 | 21.5 | 7.9 | |||

| 33.8 | 19.9 | 6.95 | |||||

| 1¼ | 42.8 | 13 | 30.2 | 7.9 | |||

| 42.55 | 28.7 | 6.95 | |||||

| 1½ | 48.9 | 13 | 34.7 | 8.9 | |||

| 48.65 | 33.2 | 7.8 | |||||

| 2 | 61.35 | 16 | 43.6 | 10.9 | |||

| 61.1 | 42.1 | 9.5 | |||||

| Nps | Laying Lengths | ||||||

| Coupling | Half Coupling | ||||||

| E | F | ||||||

| 1/2. | 9.5 | 22.5 | |||||

| 3/.4 | 9.5 | 23.5 | |||||

| 1 | 13 | 29 | |||||

| 1¼ | 13 | 30 | |||||

| 1½ | 13 | 32 | |||||

| 2 | 19 | 41 | |||||

General Notes:

Dimensions are in millimeters unless otherwise indicated.

Socket Bore (B) – Maximum and Minimum dimensions.

Bore Diameter (D) – Maximum and Minimum dimensions.

Socket wall thickness – (C) – Average of Socket wall thickness.

Dimensional tolerances laying lengths – (E & F)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2½ to NPS 4 = +/- 2.5 mm

MARKING & PACKING:

PRODUCTS ARE PACKAGED TO ENSURE THAT THERE IS NO DAMAGE DURING TRANSIT. IN CASE OF EXPORTS, STANDARD EXPORT PACKAGING IS DONE IN WOODEN CASES. ALL FORGED FITTINGS ARE MARKED WITH GRADE, LOT NO, SIZE, DEGREE AND OUR TRADE MARK.

Call +91 9833907060

Call +91 9833907060 Send E-mail

Send E-mail