Manufacturer, Exporter & Supplier Of Asme B16.11 Socket Weld Tee, Asme B16.11 Socket Weld Tee Dimensions, Socket Weld Tee , Socket Weld Fittings

Asme B16.9 Socket Weld Tee, Asme B16.11 Socket Weld Tee Dimensions, Asme B16.11 Socket Weld Tee At Best Price With High Quality

Doshi Impex India Is A Dynamic Group, Which Was Established Over A Decade Ago To Cater To Growing Demands Of Asme B16.11 Socket Weld Tee

We Manufacture, Export And Supply Socket Weld Fittings Which Meets With National And International Quality Standards And Producing Base Which Owns Equipments Conforming To International Technical Level And Is Well Equipped With A Whole Set Of Advanced Plasma Refining Equipments.

Tee Straight And Reducing Tee

This Would Help To Make A 90 Degree Branch From The Main Run Of The Pipe. Socket Weld Reducing Tee Is With A Smaller Diameter Branch Which Connecting The Smaller Pipe Branch.

| Description | Class Designation | ||

| 3000 | 6000 | 9000 | |

| Tees | 1/2-4. | 1/2-2. | 1/2-2. |

| Pipe Size | |||

| By Wall Thickness | Sch 80 / Xs | Sch 160 | Xxs |

Forged Socket Weld Stainless Steel Fittings

- Stainless Steel – Astm A182 F304, F304l, F306, F316l, F304h, F309s, F309h, F310s, F310h, F316ti, F316h, F316ln, F317, F317l, F321, F321h, F11, F22, F91, F347, F347h, F904l, Astm A312/A403 Tp304, Tp304l, Tp316, Tp316l

- The Material For Forged Stainless Steel Fittings Conforms To Asme A182

- The Dimensions For Forged Stainless Steel Fittings Conform To Asme B16.11

· Forged Socket Weld Carbon Steel Fittings

- Carbon Steel Astm A105, A350 Lf2, A106 Gr.B, A234 Wpb

- The Material For Forged Carbon Steel Fittings Conforms To The Requirements Of Astm/Asme A105/Sa105 The Dimensions For Forged Carbon Steel Fittings Conform To Asme B16.11

|

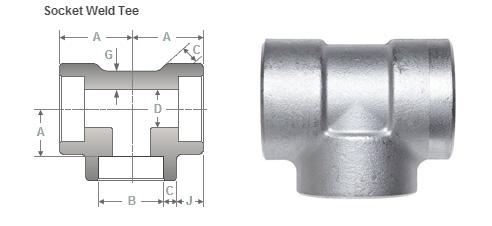

Dimensions Socket Weld Tees – Nps 1/2 To 2 – 3000 Lbs – Asme B16.11 |

||||||

| Nps | Socket | Depth | Bore | Socket | Body | Center To Bottom |

| Bore | Socket | Diameter | Wall Thickness | Wall Thickness | Of Socket | |

| B | J | D | C | G | A | |

| 1/2. | 21.95 | 10 | 16.6 | 4.65 | 3.75 | 15.5 |

| 21.7 | 15 | 4.1 | ||||

| 3/4. | 27.3 | 13 | 21.7 | 4.9 | 3.9 | 19.5 |

| 27.05 | 20.2 | 4.25 | ||||

| 1 | 34.05 | 13 | 27.4 | 5.7 | 4.55 | 22 |

| 33.8 | 25.9 | 5 | ||||

| 1¼ | 42.8 | 13 | 35.8 | 6.05 | 4.85 | 27 |

| 42.55 | 34.3 | 5.3 | ||||

| 1½ | 48.9 | 13 | 41.7 | 6.35 | 5.1 | 32 |

| 48.65 | 40.1 | 5.55 | ||||

| 2 | 61.35 | 16 | 53.5 | 6.95 | 5.55 | 38 |

| 61.1 | 51.7 | 6.05 | ||||

| 2½ | 74.2 | 16 | 64.2 | 8.75 | 7 | 41.5 |

| 73.8 | 61.2 | 7.65 | ||||

| 3 | 90.15 | 16 | 79.5 | 9.5 | 7.6 | 57.5 |

| 89.8 | 46.4 | 8.3 | ||||

| 4 | 115.8 | 19 | 103.8 | 10.7 | 8.55 | 66.5 |

| 115.45 | 100.7 | 9.35 | ||||

Call +91 9833907060

Call +91 9833907060 Send E-mail

Send E-mail