Threaded Pipe Fittings NIPPLES manufacturing and exporting.

We Recognize as a Trusted Manufacturers, Suppliers, & Exporters of Stainless Steel Threaded Pipe Nipple – ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 in all Dimensions and sizes.

Materials used in manufacturing different types of Forged Threaded Pipe Nipples includes Stainless Steel, Duplex & Super Duplex Steel, Nickel Alloy, Copper Alloy, Carbon Steel, Alloy Steel, Hastelloy, Monel, Inconel, Titaniun, Incoloy, Alloy 20, 254 SMO, Mild Steel(MS), Brass.

In plumbing and piping, a Threaded Pipe Nipple could be fitting, comprising of a brief piece of pipe, ordinarily given with a male pipe thread at each end, for interfacing two other fittings. The length of the Threaded Brass Pipe Nipples is ordinarily indicated by the overall length with thread. It may have a hexagonal section within the center for wrench to get a handle on sometimes referred to as a “hex nipple”, or it may essentially be made from a short piece of pipe sometimes referred to as a “barrel nipple” or “pipe nipple”. A “Close Threaded Pipe Nipple” has no unthreaded region; when screwed tightly between two female fittings, very small of the nipple remains exposed

| Nominal Pipe Size (NPS) | Outside Diameter | End To End “A” | Wall Thickness | ||||||||

| Large End D1 | Small End D2 | T1 | T2 | ||||||||

| Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | ||||

| 1/4”x1/8” | 13.7 | 10.3 | 57 | 2.2 | 3 | 3.7 | 6.1 | 1.7 | 2.4 | ||

| 3/8”x1/8” | 17.1 | 10.3 | 64 | 2.3 | 3.2 | 4 | 6.4 | 1.7 | 2.4 | ||

| 3/8”x1/4” | 17.1 | 13.7 | 64 | 2.3 | 3.2 | 4 | 6.4 | 2.2 | 3 | ||

| 1/2”x1/8” | 21.3 | 10.3 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 1.7 | 2.4 | ||

| 1/2”x1/4” | 21.3 | 13.7 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.2 | 3 | ||

| 1/2”x3/8” | 21.3 | 17.1 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.3 | 3.2 | ||

| 3/4”x1/8” | 26.7 | 10.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 1.7 | 2.4 | ||

| 3/4’x1/4” | 26.7 | 13.7 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.2 | 3 | ||

| 3/4”x3/8” | 26.7 | 17.1 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.3 | 3.2 | ||

| 3/4”x1/2” | 26.7 | 21.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1”x1/8” | 33.4 | 10.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 1.7 | 2.4 | ||

| 1”x1/4” | 33.4 | 13.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.2 | 3 | ||

| 1”x3/8” | 33.4 | 17.1 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.3 | 3.2 | ||

| 1”x1/2” | 33.4 | 21.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1”x3/4” | 33.4 | 26.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4”x1/8” | 42.2 | 10.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 1.7 | 2.4 | ||

| 1-1/4”x1/4” | 42.2 | 13.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.2 | 3 | ||

| 1-1/4”x3/8” | 42.2 | 17.1 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.3 | 3.2 | ||

| 1-1/4”x1/2” | 42.2 | 21.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/4”x3/4” | 42.2 | 26.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4”x1” | 42.2 | 33.4 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2”x1/8” | 48.3 | 10.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 1.7 | 2.4 | ||

| 1-1/2”x1/4” | 48.3 | 13.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.2 | 3 | ||

| 1-1/2”x3/8” | 48.3 | 17.1 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.3 | 3.2 | ||

| 1-1/2”x1/2” | 48.3 | 21.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/2”x3/4” | 48.3 | 26.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/2”x1” | 48.3 | 33.4 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2”x1-1/4” | 48.3 | 42.2 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2”x1/8” | 60.3 | 10.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 1.7 | 2.4 | ||

| 2”x1/4” | 60.3 | 13.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.2 | 3 | ||

| 2”x3/8” | 60.3 | 17.1 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.3 | 3.2 | ||

| 2”x1/2” | 60.3 | 21.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 2”x3/4” | 60.3 | 26.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 2”x1” | 60.3 | 33.4 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.4 | 4.5 | 6.4 | 9.1 |

| 2”x1-1/4” | 60.3 | 42.2 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2”x1-1/2” | 60.3 | 48.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 3.7 | 5.1 | 7.1 | 10.2 |

| 2-1/2”x1/8” | 73 | 10.3 | 178 | 5.2 | 7 | 9.5 | 14 | 1.7 | 2.4 | ||

| 2-1/2”x1/4” | 73 | 13.7 | 178 | 5.2 | 7 | 9.5 | 14 | 2.2 | 3 | ||

| 2-1/2”x3/8” | 73 | 17.1 | 178 | 5.2 | 7 | 9.5 | 14 | 2.3 | 3.2 | ||

| 2-1/2”x1/2” | 73 | 21.3 | 178 | 5.2 | 7 | 9.5 | 14 | 2.8 | 3.7 | 4.8 | 7.5 |

| 2-1/2”x3/4” | 73 | 26.7 | 178 | 5.2 | 7 | 9.5 | 14 | 2.9 | 3.9 | 5.6 | 7.8 |

| 2-1/2”x1” | 73 | 33.4 | 178 | 5.2 | 7 | 9.5 | 14 | 3.4 | 4.5 | 6.4 | 9.1 |

| 2-1/2”x1-1/4” | 73 | 42.2 | 178 | 5.2 | 7 | 9.5 | 14 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2-1/2”x1-1/2” | 73 | 48.3 | 178 | 5.2 | 7 | 9.5 | 14 | 3.7 | 5.1 | 7.1 | 10.2 |

| 2-1/2”x2” | 73 | 60.3 | 178 | 5.2 | 7 | 9.5 | 14 | 3.9 | 5.5 | 8.7 | 11.1 |

| 3”x1/8” | 88.9 | 10.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 1.7 | 2.4 | 3.2 | 4.8 |

| 3”x1/4” | 88.9 | 13.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.2 | 3 | 3.7 | 6.1 |

| 3”x3/8” | 88.9 | 17.1 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.3 | 3.2 | 4 | 6.4 |

| 3”x1/2” | 88.9 | 21.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 3”x3/4” | 88.9 | 26.7 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 3”x1” | 88.9 | 33.4 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 3”x1-1/4” | 88.9 | 42.2 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 3”x1-1/2” | 88.9 | 48.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.7 | 5.1 | 7.1 | 10.2 |

| 3”x2” | 88.9 | 60.3 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 3.9 | 5.5 | 8.7 | 11.1 |

| 3”x2-1/2” | 88.9 | 73 | 203 | 5.5 | 7.6 | 11.1 | 15.2 | 5.2 | 7 | 9.5 | 14 |

| 3-1/2”x1/8” | 101.6 | 10.3 | 203 | 5.7 | 8.1 | 1.7 | 2.4 | ||||

| 3-1/2”x1/4” | 101.6 | 13.7 | 203 | 5.7 | 8.1 | 2.2 | 3 | ||||

| 3-1/2”x3/8” | 101.6 | 17.1 | 203 | 5.7 | 8.1 | 2.3 | 3.2 | ||||

| 3-1/2”x1/2” | 101.6 | 21.3 | 203 | 5.7 | 8.1 | 2.8 | 3.7 | 4.8 | 7.5 | ||

| 3-1/2”x3/4” | 101.6 | 26.7 | 203 | 5.7 | 8.1 | 2.9 | 3.9 | 5.6 | 7.8 | ||

| 3-1/2”x1” | 101.6 | 33.4 | 203 | 5.7 | 8.1 | 3.4 | 4.5 | 6.4 | 9.1 | ||

| 3-1/2”x1-1/4” | 101.6 | 42.2 | 203 | 5.7 | 8.1 | 3.6 | 4.9 | 6.4 | 9.7 | ||

| 3-1/2”x1-1/2” | 101.6 | 48.3 | 203 | 5.7 | 8.1 | 3.7 | 5.1 | 7.1 | 10.2 | ||

| 3-1/2”x2” | 101.6 | 60.3 | 203 | 5.7 | 8.1 | 3.9 | 5.5 | 8.7 | 11.1 | ||

| 3-1/2”x2-1/2” | 101.6 | 73 | 203 | 5.7 | 8.1 | 5.2 | 7 | 9.5 | 14 | ||

| 3-1/2”x3” | 101.6 | 88.9 | 203 | 5.7 | 8.1 | 5.5 | 7.6 | 11.1 | 15.2 | ||

| 4”x1/4” | 114.3 | 13.7 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.2 | 3 | ||

| 4”x3/8” | 114.3 | 17.1 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.3 | 3.2 | ||

| 4”x1/2” | 114.3 | 21.3 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 4”x3/4” | 114.3 | 26.7 | 229 | 6 | 8.6 | 13.5 | 17.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 4”x1” | 114.3 | 33.4 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.4 | 4.5 | 6.4 | 9.1 |

| 4”x1-1/4” | 114.3 | 42.2 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.6 | 4.9 | 6.4 | 9.7 |

| 4”x1-1/2” | 114.3 | 48.3 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.7 | 5.1 | 7.1 | 10.2 |

| 4”x2” | 114.3 | 60.3 | 229 | 6 | 8.6 | 13.5 | 17.1 | 3.9 | 5.5 | 8.7 | 11.1 |

| 4”x2-1/2” | 114.3 | 73 | 229 | 6 | 8.6 | 13.5 | 17.1 | 5.2 | 7 | 9.5 | 14 |

| 4”x3” | 114.3 | 88.9 | 229 | 6 | 8.6 | 13.5 | 17.1 | 5.5 | 7.6 | 11.1 | 15.2 |

| 4”x3-1/2” | 114.3 | 101.6 | 229 | 6 | 8.6 | 13.5 | 17.1 | 5.7 | 8.1 | ||

|

1. Dimensions in Millimeters. |

||

| 2. Wall Thickness:T1 & T2 in accordance with ASME B36.10M | ||

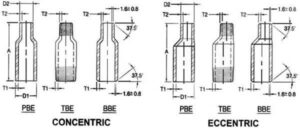

| PBE:Plain Both Ends | BBE:Bevel Both Ends | TBE:Thread Both Ends |

| PSE:Plain Small End | BSE:Bevel Small End | TSE:Thread Small End |

| PLE:Plain Large End | BLE:Bevel Large End | TLE:Thread Large End |

Call +91 9833907060

Call +91 9833907060 Send E-mail

Send E-mail